Equipment

Vapor Compression Still

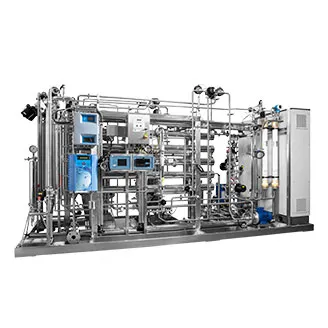

The Vapor Compression Still (VCS) produces distilled water for injectable use or WFI, compliant with the requirements of the International Pharmacopeias including USP, EP and JP.

Our VCS is available in two different versions, leveraging different technologies: falling film or rising film, depending on process needs.

Our VCS technology is the result of decades of experience and continuous technical improvement. It offers two variations: rising film and falling film. The rising film VCS showcases our expertise in distillation, with ongoing refinements to ensure exceptional performance. On the other hand, the falling film VCS represents the cutting-edge solution in VMC technology, placing special emphasis on sustainability, particularly in energy and water conservation. This version stands as the pinnacle of our 50-year journey in mastering falling film heat transfer.

Stilmas’ VCS is able to generate from 100 to 24.000 liters per hour of hot or ambient WFI. The variable wide range of production capacities allows the user to dial in required flowrates.

Application fields

Application fields

|

|

|

|

|

|

Technical description

Stilmas' VCS (Vapor Compression Still) accepts softened water that through a set of exchangers for energy recovery enters in the main column where it evaporates. The steam, decontaminated through different techniques, is subsequently compressed by a sanitary compressor and released in the condenser where it condensates and becomes WFI.

Reduced Operating Costs

- Self-modulating system adapts the production flow rate to the storage tank level to minimize water consumption due to start/stop transient.

- Due to low operating temperature, no cooling water is required and very raw water could be used (at least softened type)

- The system features a sophisticated and efficient energy recovery mode developed through pinch technology.

- To further improve water efficiencies, during low demand each system automatically adjust the blow down to minimize the water consumption

- Falling film version works with a small quantity of water inside the evaporation column, 90% less, compared the traditional configuration thus allowing 65% less starting time

- With Falling Film version No hot stand-by required allowing less energy consumption.